Our cryogenic RFID products can be used to RFID enable the storage of straw vitrification devices at cryogenic temperatures, enhancing the efficiency, traceability, and security of the storage process.

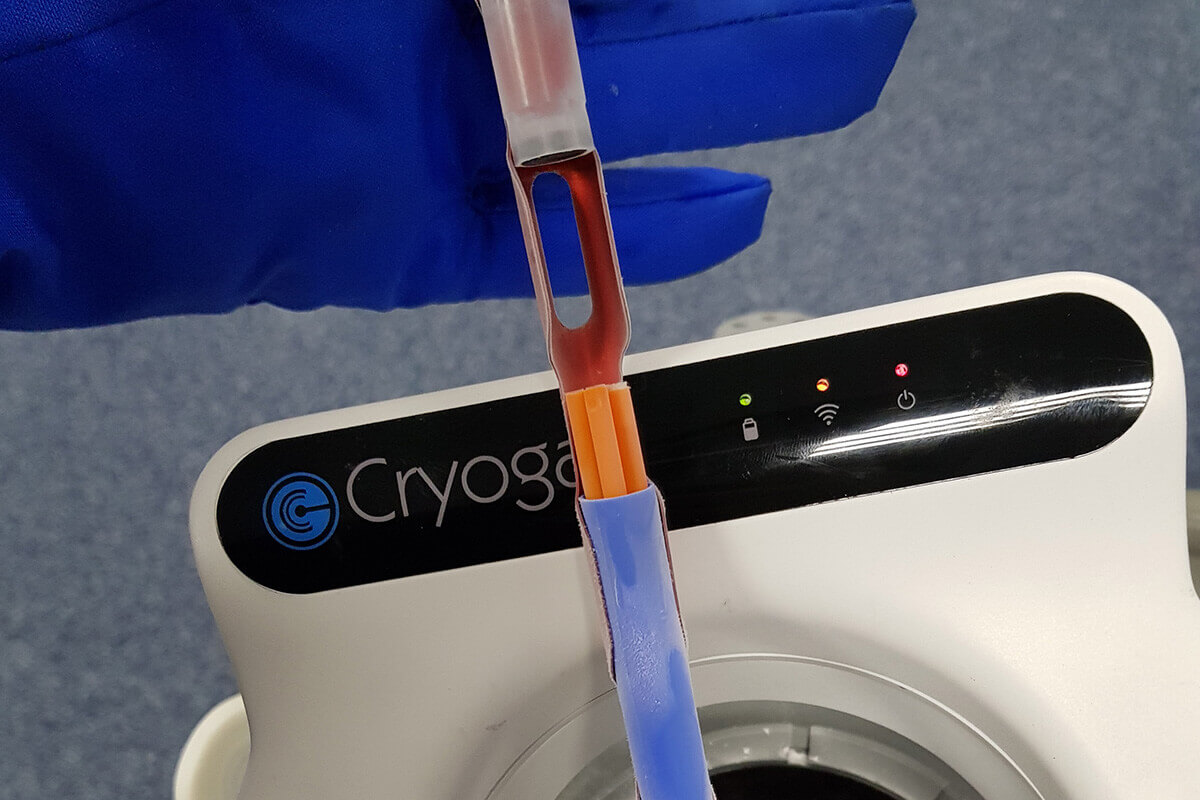

Our RFID straw sleeves can be inserted onto each straw sample to enable precise sample identification and eliminate the risk of mix-up.

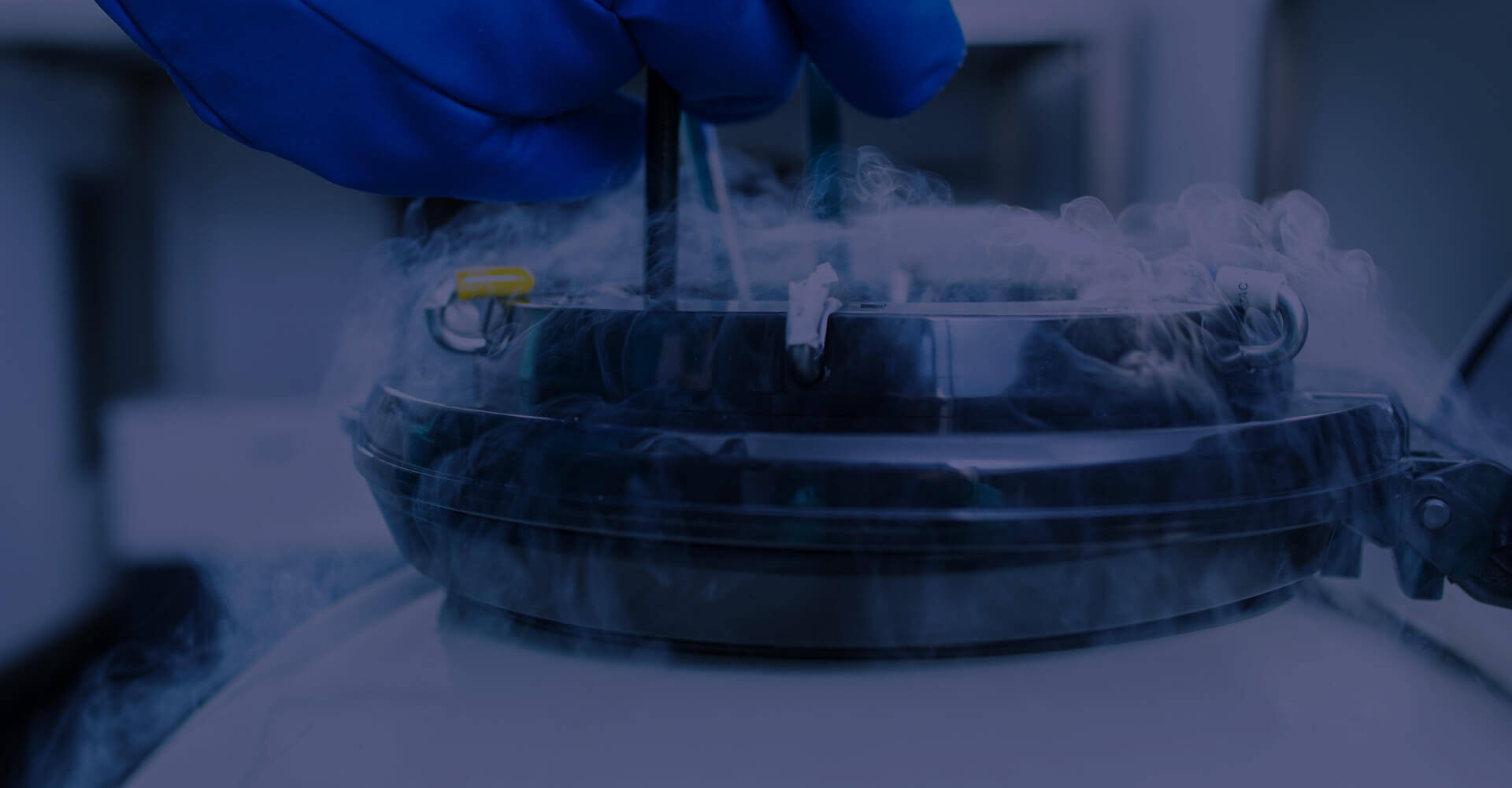

Our RFID Dewar neck reader allows for bulk reading of samples which greatly improves the laboratory’s operational efficiency. A full cane of samples can be automatically processed within a few seconds.

RFID tags do not require direct line of sight for sample identification. This means that frosted samples can be identified instantly without the need for wiping off the frost.

RFID tagging supports regulatory compliance by providing a comprehensive digital trail of sample movement. This simplifies auditing processes and helps labs adhere to quality standards.